The PIT Test proces manual

- Gadi Lahat

- Dec 19, 2025

- 6 min read

Updated: Dec 25, 2025

A Pile Integrity Test (PIT) combined with Pile Echo Test (PET) provides essential diagnostic insights into the integrity of pile foundations. These tests are vital for ensuring the safety, stability, and long-term performance of structures by detecting any potential weaknesses or defects in the deep pile foundations. Site engineers and field workers conducting these tests need to follow a well-organized, systematic process to ensure accurate results.

In this comprehensive guide, we’ll walk you through the complete process of conducting a PIT test with PET technology. This will cover everything from pile preparation to data collection, interpretation, and final reporting. By following these steps, you can ensure reliable testing outcomes and gain a deeper understanding of pile performance.

The Importance of PIT with PET Testing

Pile foundations are crucial for the stability of structures such as buildings, bridges, and other large infrastructures. Over time, the integrity of these piles can be compromised due to factors such as soil movement, corrosion, or poor installation practices. A PIT test combined with PET technology is a non-destructive way to assess the pile’s condition and identify potential flaws and defects.

Unlike traditional testing methods, which may involve excavation or pile replacement, PIT with PET allows for real-time analysis of the pile’s integrity without causing any damage. The results obtained from this testing can guide engineers in making informed decisions, preventing costly repairs or replacements later in the project.

By the end of this guide, you’ll have a thorough understanding of the process, from preparation through to result interpretation and report generation.

Pile Preparation: Laying the Groundwork

The first step in conducting a successful PIT test with PET is proper pile preparation. The pile must be ready to undergo testing to get the most accurate results.

Cleaning the Pile Head

A clean pile head is essential to ensure there’s good contact between the pile and the sensors that will be used during the test. This means thoroughly cleaning the pile’s surface to remove any dirt, debris, or corrosion. This will help eliminate potential sources of interference and provide a smooth, stable surface for the sensors to work effectively.

Use wire brushes or compressed air to clean off debris.

Ensure the pile surface is free from, oil, or other contaminants.

Putty Application

Start by applying putty to the PET device . This putty helps create a smooth interface between the pile and testing devices. The putty helps eliminate air gaps that might interfere with the testing process, ensuring a better acoustic coupling between the pile and the sensors.

Impact Sampling and Smart Trigger

Once the pile is prepared and settled, the next step is to begin the PIT test itself, focusing on impact sampling and activating the Smart Trigger function within the PET system.

Impact sampling refers to the application of force via a hammer or impact tool. This force generates waves that travel down the pile, and these waves reflect back to the sensors. These reflected signals contain valuable information about the pile’s condition. For example, irregularities such as voids, cracks, or soft spots in the pile can cause the waves to behave differently. By measuring the response time and strength of these reflected signals, engineers can assess the condition of the pile at various depths.

Impact sampling generates waves that travel down the pile and return to the sensors.

This data helps identify voids, cracks, or weak spots in the pile’s structure.

The Smart Trigger function is an essential part of this process. The Smart Trigger system ensures that the PET equipment is activated at the right moment to capture the most accurate data. It eliminates unnecessary noise by precisely triggering the equipment when the wave is at its most reliable point of detection. This feature is especially useful in situations where the pile has varying properties, as it can adapt to different signal strengths and impacts. Hence, it does not trigger just by signal strength (which can also be noise) but the signal characteristics or basic shape.

Software Settings and Calibration

Once you’ve initiated the impact sampling, the next step is to set the PIT software for optimal performance. This is where technical expertise is essential. Proper software settings ensures that the equipment is set to work with the pile’s specific characteristics. Such settings as filtering, amplification and sharpening.

You must input the correct pile parameters into the system. This includes factors such as expected pile length, material composition or wave speed. These parameters help the system analyze the impact signals in a way that is specific to the pile type being tested. Inaccurate pile data can lead to erroneous results, so take the time to double-check the settings before proceeding per pile. If many piles are the same by design and make, the PET allows to make the same setting to a group of piles, which saves time at the construction site.

Data Collection and Signal Processing

Once the system is set and the test is underway, data collection begins. The impact waves are generated, travel through the pile, and then return to the sensors, where the software processes these signals to produce meaningful data.

Each signal contains important information about the pile’s structural integrity. The strength, delay, and shape of the signals indicate whether the pile is solid, whether there are voids or cracks, and if there are any other irregularities that could compromise the pile’s load-bearing capacity. Engineers analyze these signals to determine the location and extent of any defects within the pile and also its estimated actual length

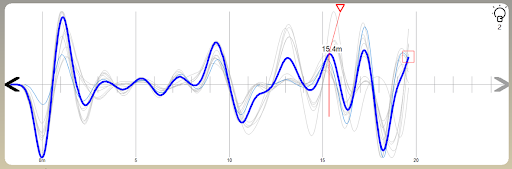

The software also analyzes the signals to determine the pile's overall waveform. A normal waveform will be consistent across the pile, indicating a healthy structure. Irregularities in the waveform suggest weak spots or anomalies in the pile that require further investigation.

Before

This is a reflection of a good pile

And this is a reflection of a pile with a flaw

Report Generation and Results Interpretation

Once the data collection is complete, the final step is to analyze the results and generate a comprehensive report. The PIT test report should provide a clear summary of the test methodology, results, and any conclusions drawn from the data.

Start by documenting the test setup, including the equipment used, the pile specifications, and the testing parameters. This ensures that the results are reproducible and provides transparency in case the results need to be reviewed by others.

The core of the report should focus on the analysis of the data. Present the impact signals, the strength of the reflected signals, and any anomalies that were detected. Highlight specific areas where the pile’s integrity may be compromised, and include recommendations for addressing these issues. PET allows you to make your report in MS Word, and incluse your logo, images from the construction site, and full easy text remarks along with the impact reflections. This is also well explained in this blog post

If delayed or weak signals are detected, it may suggest the presence of cracks, voids, or material inconsistencies.

Based on these findings, further testing, remediation, or even pile replacement may be necessary.

Finally, the report should summarize the overall health of the pile and whether it meets the required standards for load-bearing capacity. If problems are detected, the report should suggest corrective actions, such as re-driving the pile, grouting, or taking further steps to repair the compromised areas.

Conclusion

PIT with PET testing is an invaluable tool for assessing the health and stability of pile foundations in construction projects. By carefully preparing the pile, calibrating the software, sampling impact waves, and analyzing the data, engineers and field workers can accurately determine the condition of the pile and identify any potential issues.

By following the steps outlined in this guide, you can ensure that the PIT test is performed correctly, data is collected with precision, and results are interpreted accurately. For more information on PIT and PET testing and to access professional services, visit PileTest’s website.

Frequently asked questions

What are the newest NDT methods for piles?

AI-assisted analysis, wireless sensors, tomography, robotics, PSI, and big data are the leading innovations.

How does AI improve pile testing accuracy?

AI interprets stress-wave data quickly, detects subtle anomalies, and predicts potential future issues.

Are wireless sensors reliable for real-time monitoring?

Yes, they provide continuous data without manual intervention and integrate with AI systems for automated analysis.

Can robotics replace human engineers in NDT?

Robotics reduces manual work and enhances consistency, but engineers are still required to interpret results and make decisions.

Why is big data important for pile testing?

Big data enables predictive maintenance, trend analysis, benchmarking, and more informed decision-making for large projects.

Comments