How Does Low-Strain Integrity Testing Detect Flaws in Piles?

- Gadi Lahat

- Aug 22, 2025

- 5 min read

Updated: Aug 24, 2025

When constructing deep foundations, ensuring the integrity of buried piles is critical—but most of the structure lies hidden beneath the surface. That’s where low-strain integrity testing (often called PIT or Pulse-Echo Method) comes in. It offers a fast, non-destructive way to check for hidden flaws like cracks, voids, and necking in concrete or cast-in-place piles.

In this article, we’ll break down the mechanics behind wave reflection testing, explain how flaws are detected, and walk through the standards and practical limitations that come with low-strain testing or pile integrity testing - especially using tools like the PET system by Piletest.

1. Understanding the Basics of Low-Strain Pile Integrity Testing (PIT)

What Is the Pulse-Echo Method?

The Pulse-Echo Method involves lightly tapping the pile head with a handheld hammer while capturing vibration waves with a sensitive sensor. These stress waves travel down the pile and reflect back when they encounter a change in impedance—such as the pile toe or a flaw in the shaft.

The return signal is recorded and displayed as a reflectogram. Engineers then analyse these signals to assess pile length, integrity, and possible defects.

Applications in Deep Foundation Assessment

Low-strain testing is ideal for:

· Bored and driven concrete piles

· Cast-in-place shafts ·

· Quality assurance post pile construction

It’s a fast, affordable alternative to more intrusive methods—and it works even when only the pile head is exposed.

A Modern Tool for the Job: PET by Piletest

The PET (Pile Echo Tester) is a widely used low-strain device that connects to Android phones, tablets, or PCs. It enables:

· USB/Bluetooth connectivity

· Instant waveform capture

· On-site interpretation

· Compliance with ASTM D5882, AFNOR P160-2,4 standards

2. The Science Behind Wave Propagation in Piles

Compression Waves and Reflections

When a small hammer impact hits the pile, it generates a compression wave that travels downward at a known velocity (typically around 4,000 m/s in concrete). If the pile is uniform, the wave reflects upwards from the toe.

But if there’s a flaw—such as a void, honeycombing, or significant necking—it creates a secondary reflection that returns earlier than expected.

Wave Speed and Pile Material Properties

To analyze wave reflections correctly, you must understand the material-dependent wave velocity. Concrete piles have predictable velocities, but variability due to curing or mix design can introduce interpretation challenges.

3. Reflectograms and What They Tell Us

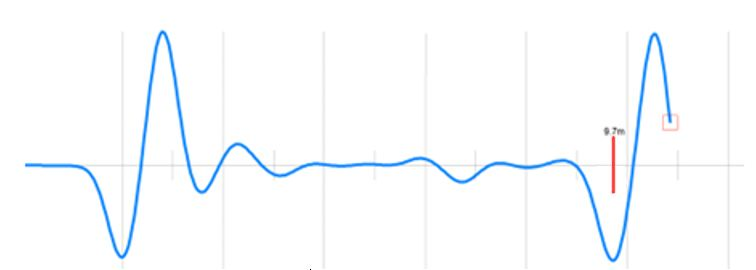

What Does a Good Reflectogram Look Like?

A clean, uniform pile shows:

· A sharp toe reflection at the expected depth (marked in red above)

· Minimal noise

· No unexpected early reflections

Identifying Cracks, Voids, Necking

Common reflectogram anomalies include:

· Early reflection → Likely crack or necking

· Attenuated signal → Possible material deterioration

· Multiple wavelets → Layering, bulges, or soil-pile interface issues

Engineers cross-reference wave arrival times and amplitudes to estimate flaw locations.

False Positives from Soil or Velocity Errors

Soil resistance can absorb or scatter wave energy, especially in soft or layered soils. Similarly, inaccurate assumptions about wave velocity can lead to depth miscalculations.

Good practice involves:

· Conducting comparative tests on multiple piles

· Calibrating wave speed using known pile lengths

· Reviewing soil bore logs to anticipate damping effects

4. Standards & Protocols That Govern PIT Accuracy

ASTM D5882 Overview

The key governing standard for low-strain integrity testing is ASTM D5882. It outlines:

· Equipment specifications

· Minimum pile top prep (clean, flat, dry)

· Signal resolution and gain settings

· Required number of test points per pile

· Interpretation guidelines

Device Calibration and Limitations

Even rugged systems like PET must be:

· Calibrated regularly (sensor using the software)

· Kept free from mechanical looseness or connector issues

· Used with consistent hammer energy across piles

5. Factors That Affect PIT Readings and Interpretation

Soil Resistance, Toe Response Lag

Some piles end in hard or granular soils, which may dampen the toe response or cause phase shifts. This makes it harder to confirm pile length without misinterpretation.

Impact Energy and Hammer Consistency

Too light an impact = weak signal. Too hard = oversaturation. Consistency is key. Good devices like the PET make it easy to collect many (20-50) impacts, automatically select the cleanest impacts, and average the selected impacts to obtain a good and clean reflectogram.

Some field teams use hammers with integrated force sensors for reproducibility. This, however, has been found to add little to no added information to what the velocity reflectogram provides.

Operator Experience and Software Algorithms

A well-trained operator backed by interpretation software (like Piletest’s PET software) can analyse:

· Wave attenuation

· Overlaid test results across similar piles

· Real vs. pseudo anomalies

· Filter, Sharpen and amplify the recorded impacts

6. Why We Don’t Test 100% of Piles—And Should We?

The Risk-Based Testing Approach

In many projects, only 2–5% of piles are tested. The logic: test a representative sample, then test more only if problems arise.

But as this Piletest article explains, that strategy assumes pile uniformity, which may not reflect reality. We find this practice dangerous, and we do not recommend it. Test all piles.

PIT as Part of a Larger QA/QC Plan

PIT should complement, not replace:

· Static or dynamic load testing

· Crosshole sonic logging (CSL)

Testing 100% of piles adds cost—but also confidence. For critical structures or poor site conditions, full testing may be essential.

When 100% Testing Becomes Necessary

· Bridges and public safety infrastructure

· High seismic zones

· Projects with past integrity issues

· Offshore wind or port foundations

· When the cost of testing is negligible considering the total cost of the pile or the possible damage cost (risk).

7. Advanced Testing Tools: PET by Piletest

Key Features and Wave Capture Accuracy

PET by Piletest is one of the few tools built specifically for rugged field use. Benefits include:

· IP68 durability

· USB/Bluetooth flexibility

· Simple Android integration

It offers full compliance with ASTM protocols and delivers accurate reflectograms—without requiring formal certification to operate.

Software Interpretation with Multi-Pile Overlays

PET lets you:

· Overlay test results from multiple piles, creating a site average

· View time vs. depth conversions

· Check for top of pile reflection using FFT and Repetitive noise ruler

· Apply filters to isolate noise

· Export customizable test reports instantly or share with the supporting engineering team

Benefits for Professionals

Whether you're in geotechnical consulting, infrastructure inspection, or construction QC, PET helps you:

· Reduce testing time

· Increase accuracy

· Streamline documentation

It’s a cost-effective option for firms that need quick integrity results—especially across remote or large job sites. Webinar presenting these features can be viewed here.

Conclusion

Low-strain integrity testing offers an accessible, accurate, and cost-effective method for verifying pile quality. By understanding wave mechanics, reflectogram patterns, and the limits of the method, engineers can confidently identify and resolve issues before they become structural risks.

Modern tools like PET by Piletest make the process easier and faster, giving you actionable data in the field—without guesswork.

FAQ Section

Q1: What’s the most common false positive in PIT?

PIT can identify cracks, necking, bulges, voids, changes in material quality, and discontinuities in pile shafts.

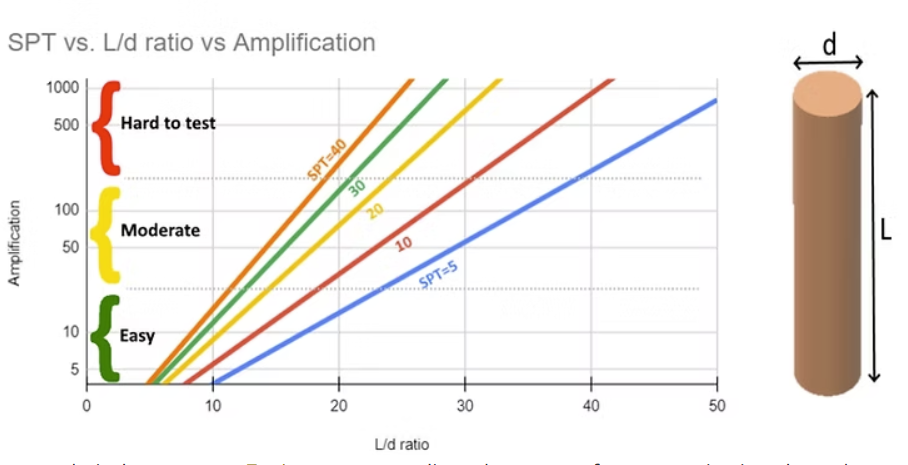

Q2: How deep can low-strain testing go?

Depending on pile dimensions (diameter to length ratio – see graph below) and soil (SPT value), PIT can detect reflections from depths up to 30 meters or more.

Q3: What are the main limitations of PIT?

It can’t assess bearing capacity or detect flaws beyond highly damped zones like dense soil layers or very slender piles.

Q4: Can PIT be used on old/existing piles?

Yes, as long as the pile head is accessible and flat enough for impact. If the top of the pile is accessible the length can be assessed even under a structure in favourable conditions.

Q5: How does soil type affect reflectogram clarity?

Soft soils (low SPT) absorb wave energy, reducing toe reflection clarity. Dense soils may reflect waves prematurely or distort timing.

See the graph below

Comments