What Is Cross Hole Sonic Logging and Why It Matters for Deep Foundation Projects

- Gadi Lahat

- Jun 11, 2025

- 6 min read

Updated: Dec 15, 2025

In the world of modern infrastructure, the strength and integrity of deep foundations play a critical role in the long-term safety of buildings, bridges, dams, and other heavy-load structures. Among the suite of non-destructive testing methods, cross-hole sonic logging (CSL) has emerged as an industry-standard technique to evaluate the internal condition of drilled shafts with bored piles.

This blog will explore what crosshole sonic logging test is, how the CSL test for piles works, and why this method is essential for deep foundation projects. We'll also look at the tools that enable accurate CSL testing—especially the CHUM system from Piletest—and outline best practices for getting the most reliable results.

Understanding Crosshole Sonic Logging (CSL)

Crosshole sonic logging test is a non-destructive testing method used to assess the integrity of concrete in deep foundation elements like cast-in-situ piles and drilled shafts. The test is conducted by transmitting ultrasonic signals between access tubes embedded in the concrete during casting. These signals travel through the concrete from a transmitter to a receiver, and any delay, distortion, or attenuation in the signal can indicate internal anomalies.

CSL testing is especially effective for detecting:

Voids or air pockets

Honeycombing

Necking or bulging in the pile

Segregation of concrete

Water penetration

It’s one of the most trusted methods when precise structural evaluation is required, and it's widely specified in standards like ASTM D6760.

How Does the Crosshole Sonic Logging Test Work?

The cross-hole sonic logging test uses a pair of access tubes (often made of steel or PVC) installed vertically by binding them to the pile reinforcement cage, within the pile prior to concrete pouring. These tubes are filled with water to facilitate the transmission of ultrasonic waves. Once the concrete has cured to the appropriate level, the test is carried out.

Step-by-Step Process:

Preparation: Ensure all access tubes are unobstructed and filled with water.

Equipment Setup: Insert a transmitter and receiver probe into adjacent tubes.

Signal Transmission: The transmitter sends out a sonic pulse, which travels through the concrete to the receiver.

Data Capture: The receiver measures arrival time, energy, and waveforms.

Interpretation: Engineers analyse the signal for signs of defects based on travel time and wave attenuation. Software also compares the values against a standard rating criterion.

The above process can also be viewed in this CSL animated video

If the wave travels more slowly or is heavily attenuated between two points, it often indicates poor-quality concrete or a physical defect.

The CHUM system by Piletest is an advanced CSL solution that provides real-time logging, high-resolution waveform capture, and intuitive data interpretation, making the process more accurate and user-friendly.

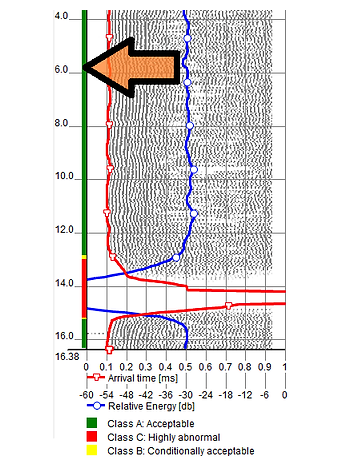

Below is the standard criteria CHUM software uses to decide the severity of the flaw (See abc class criteria on bottom of right image) - and for the embedded criteria bar (pointed by the arrow) on CSL FAT and Relative Energy graphs

Why CSL Matters in Deep Foundation Projects

In deep foundation engineering, certainty about what lies beneath the surface is not optional—it's mission-critical. That’s where cross-hole sonic logging becomes invaluable.

1. Assures Structural Integrity

CSL testing helps verify that the concrete within the pile is continuous and free of major defects. Voids or poorly compacted concrete can significantly reduce a pile’s load-bearing capacity.

2. Identifies Construction Errors

Even with modern concreting techniques, issues like improper vibration, delayed pours, or segregation can occur. A cross-hole sonic logging test for piles can detect these problems before the structure goes up.

3. Reduces Risk of Failure

Undetected defects can lead to structural instability, costly repairs, or even catastrophic failure. Early detection allows for remedial action without jeopardizing the project timeline or budget.

4. Ensures Compliance

Many international building codes and project specifications mandate CSL testing, especially for critical infrastructure. CSL is often required to validate pile quality before progressing to superstructure construction.

For contractors and project managers, using proven CSL equipment—such as those offered by Piletest—not only ensures compliance but also builds confidence with stakeholders.

Applications of Cross-Hole Sonic Logging Test for Piles

The cross-hole sonic logging test for piles is not a niche method—it is widely used across civil, structural, and geotechnical engineering projects involving:

Drilled Shafts: High-load foundation elements for bridges, towers, and skyscrapers.

Bored Piles: Common in deep urban excavations or soft soil environments.

Caissons: Used in large marine or port structures.

Tunnels and Underpasses: These are used to assess diaphragm walls and contiguous pile walls.

Pile walls or Secant walls – These are used to prepare deep building underground floors, and reinforcement walls on roads.

For instance, many highway authorities and transport infrastructure developers include CSL in their QA/QC protocols, ensuring long-term safety and durability of the constructed assets. For many construction engineers, CSL testing on the execution of their design is standard. This is especially so, as the cost of the CSL test vs the damage it can prevent makes it a sure choice.

CSL vs. Other Pile Testing Methods

Let’s explore how CSL compares with alternative testing techniques:

Method | Purpose | Limitations |

CSL | Detects internal flaws in cast-in-situ piles | Requires pre-installed access tubes |

Low-Strain Integrity Test (PIT) | Checks the pile integrity and pile toe response for length | The method is limited to slender piles and is suitable mainly for small piles. Defects at the top of the pile are preventing quality reading of defects below, and even pile toe detection. |

Gamma-Gamma Logging

| Density measurement via radiation | Expensive and limited in scope. Involves radioactive radiation |

Thermal Integrity Profiling (TIP) | Uses temperature variations to detect anomalies | Newer method with less widespread adoption. Poor resolution for defects at the centre of the pile. |

Among all, cross-hole sonic logging remains the most accurate for identifying voids and necking within the pile body. It also offers 3D imaging of defects with Tomography (3DT). View this video for 3DT demonstration

Why Engineers Choose the CHUM System for CSL

Developed by Piletest, the CHUM system is a globally recognized solution for performing high-precision cross-hole sonic logging tests.

Key Features:

Real-time waveform and travel-time display

Compatible with up to 16 access tubes for complex shaft analysis

AGC for ease of operation

Fast detection allowing pull speed of 2m per second, and the highest daily profile testing capacity on the market.

Each sensor is transmitter and receiver (transceiver) for faster operation

Cloud-based data storage and export options

Standard support for 3D Tomography viewing.

CHUM stands out for its ease of use, flexibility, and compliance with ASTM D6760, making it a preferred choice among consultants and testing agencies. You can learn more about its capabilities here.

Best Practices for Performing a Successful CSL Test

While cross-hole sonic logging is a powerful diagnostic tool, its effectiveness depends on proper planning and execution. Here are some best practices:

1. Access Tube Installation

Install at least two access tubes (preferably more for redundancy) inside the rebar cage. Make sure the tubes are securely tied and do not float or shift during the pour.

2. Use Quality Tubes

Steel tubes are often recommended over PVC, as they better bond with concrete and reduce the risk of signal interference.

3. Flush Tubes Post-Pour

Immediately after pouring, flush the tubes with water to remove debris and prevent clogging. Test all tubes for continuity before the concrete sets.

4. Wait for Optimal Curing Time

Conduct CSL testing once the concrete has cured sufficiently—usually between 3 to 7 days depending on site conditions.

5. Analyze Data with Expert Software

Use specialized CSL software (like that provided with CHUM) to analyse waveforms and detect even subtle anomalies.

Following these guidelines will ensure that your cross-hole sonic logging test for piles yields reliable and actionable data.

Future of Cross-Hole Sonic Logging

The next wave of innovation in pile integrity testing is already unfolding. Emerging trends include:

AI-Powered Defect Detection: Software that learns from thousands of CSL tests to improve anomaly identification.

Cloud-Based Collaboration: Engineers can review results remotely and in real-time.

Robotic Probes: Automated probe deployment for safer and faster testing on large sites.

Integration with Digital Twins: CSL results feed into BIM and infrastructure health monitoring platforms.

As technology evolves, CSL will continue to be the gold standard for pile integrity assessment.

Final Thoughts

In deep foundation construction, what you can’t see can hurt you. Cross-hole sonic logging is a vital tool that gives engineers visibility into the concrete quality of foundation piles. Whether you’re building a bridge, skyscraper, or offshore structure, using the cross hole sonic logging test for piles ensures your foundation is sound—before it becomes someone else’s problem.

For those seeking advanced, field-proven CSL solutions, Piletest and its CHUM system provide all the tools and support needed to ensure testing success from start to finish.